10 kV-36 kV MEDIUM VOLTAGE SWITCHGEAR FOR

Product Info

The series MV metal enclosed cells; In secondary distribution systems up to 36kV, compact kiosk type substations and industrial buildings are designed with the purpose of use in medium voltage switchgear internal spaces.

All functional units that may be required in a switching center facility can be easily side by side. Production at the factory has been completed and all routine and type tests made cells can be activated in a practical way in a very short time using it safely.

Cutting process is done with SF6 circuit breakers separation process is carried out with gas or air insulated busbars is air-insulated separators. Thus providing a secure separation and cutting measures are taken to a minimum. MV cells are used in the series of modules easily and safely in kiosk type substations with compact dimensions.

Section is air insulated busbars and wiring. Weather-proofed and equipped with SF6 gas insulated modular switching elements are composed of parts.

Cells according to the degree of protection of MV IP.3X and continuity class facilities LSC2-PM has been approved by accredited testing should be taken to classify types of laboratory test report ..

IEC 62271-200, 62271-200 standards TS EN ISO 9001: 2008 is manufactured in accordance with quality standards. Installation, Connection and monitoring control operations are carried out from the front.

Design and Structural Properties;

Cell Structure

Cells cabinet type, suitable for use in building (built-in type, IP3X) are produced.

• The cells are composed of sections according to the following functional properties.

1.Anabar division,

2.Anahtarl partition (separator, switch-disconnectors or gas separator),

3.Kablo / bus connections and devices division, (breakers, fuses, metering transformers, earthing switches, etc.).

4.İşlet mechanisms section (Separator, load break switch, breaker, earthing switch mechanisms)

5.Alçak voltage section (protection, control and measurement boards) These sections are separated by a sheet of separator plates and body or load break from each other.

• Cell carcasses of 2 mm electro galvanized steel, painted parts are manufactured without the use of funds from the 1.5-2 mm DKP sheet.

• visible from the front sheet metal parts are painted with electrostatic powder coating based on polyester.

STANDARD EQUIPMENT

1.Dön Separator / SF6 Gas Separators

2.SF6 Gas Circuit Breakers / vacuum breakers

3.O.G. Current Transformer

4.Alçak Voltage Cabinet

Movement control 5.Ayırıc

6.Termostat Controlled Heater

7.Hücr to Domestic Ground

8.Toprak Separators

9.Kablo fixture

A.G 04 kV DISTRIBUTION PANELS

Product Info

Standing f.I. Distribution Panels are used in order to feed the power distribution board and give the energy field. Main Supply is further distributed to all centers can be controlled from a single point. 0.4 kV Low Voltage Panels can also be manufactured to our current capacity by 6300. Domestic and Abroad Factory, Tourism Facilities, Hotels, Airports, and is used in the energy distribution in residential business. Optionally, 0.4 kV in our transparent door panel can be connected to customer preferences.

STANDARD FEATURES;

Home Carcass Body 1.5 / 2mm

Doors 1.5 mm / 2 mm

Cover Sheet 1 / 1,2 / 1,5 mm

Electro-static epoxy polyester paint RAL 7035 (all RAL colors Optional)

Galvanized or Painted Steel Mounting Plate

Removable side and rear doors for ease of field installation and connection

Cable entry from above or below

TS-3367 EN60439-1, EN60439-1 TS-3367 / A1

TECHNICAL SPECIFICATIONS;

Rated insulation voltage of 690 V

Rated operating voltage 400

Nominal frequency of 50 Hz

Rated current 6300 up to

Protection Class IP 20 - IP 65

OPTIONAL FEATURES;

Front Door Glass or plexiglass from manufacturing

Color all RAL colors in paint manufacturing

Dimensions; Special production upon customer request

The ventilation system or air conditioning fan

COMPENSATION BOARD

Product Info

The electrical energy; is produced from plants, until it reaches the load is consumed various losses occur. Reactive energy; In case of withdrawal unnecessarily loaded network efficiency and capacity utilization of network resources is reduced, increasing the losses. Electrical machinery uses reactive power or reactive power from the grid give the network. This engine electrical system reactive power, which is used to supply the necessary magnetic field for operation elements such as transformers, power becomes the active current is the part that makes the actual work. Increasing efficiency and a compensation capacitor to the input of the inductive system to avoid exposure to reactive power generated in the system is stored in the capacitor network connected to the inductive reactive power grid without Compensation Boards; businesses reduce costs in meeting the business using the inductive reactive power they draw from the grid. If there is more load on the business of the harmonics using the harmonic harmonic filter reactors in compensation board protection from damage caused by the network are provided.

Inside Compensation Board,

a) Capacitors,

b) Harmonic Reactors

c) Reactive Power Control Relay

d) Compensation system for contactors

e) the Insured Cutters

f) Ventilation fans

MCC / DCC MOTOR CONTROL PANELS

Product Info

Our MCC Motor Control and Automation Panel can be made at the appropriate size according to all kinds of design and layout. Our MCC Panels variety of automation, factory engine control systems, fans, and is used everywhere in need of automation in the ventilation system.

STANDARD FEATURES;

Home Carcass Body 1.5 / 2mm

Doors 1.5 mm

Cover Sheet 1 / 1,2 / 1,5 mm

Electro-static epoxy polyester paint RAL 7035 (all RAL colors Optional)

Galvanized or Painted Steel Mounting Plate

Removable side and rear doors for ease of field installation and connection

Cable entry from above or below

TS-3367 EN60439-1, EN60439-1 TS-3367 / A1

TECHNICAL SPECIFICATIONS;

Rated insulation voltage of 690 V

Rated operating voltage 400

Nominal frequency of 50 Hz

Rated current 6300 up to

Protection Class IP 20 - IP 65

OPTIONAL FEATURES;

Front Door Glass or plexiglass from manufacturing

Color all RAL colors in paint manufacturing

Dimensions; Special production upon customer request

The ventilation system or air conditioning fan

PANEL METER

Product Info

Our Turkey Electricity Authority and counters made of various types of power generation panels can be made in accordance with the specifications in the external and internal types. Our application fields of housing and building systems in low voltage panel of people, goods and securing the safety of our manufacturing and assembly is done by keeping in the forefront. Our panel meter housing, shopping centers, factories in Turkey Electricity Authority is used for billing or billing company. Billing transactions via smart meters could be performed by CE SCADA automation.

PLASTER PANELS AND FLUSH

Product Info

Recessed and Surface Mounted Panels; Lighting and outlets and distribution system in place that can be made of boards are sized according to the space. Energization of electrical equipment, lighting outlet feeds, fan, engine closest to the field equipment are energized by these panels.

STANDARD FEATURES;

Home Carcass Body 1 / 1,2 / 1,5 mm DKP sheet

Doors 1.5 mm

Cover Sheet 1 / 1,2 / 1,5 mm

Electro-static epoxy polyester paint RAL 7035 (all RAL colors Optional)

Galvanized or Painted Steel Mounting Plate

Removable side and rear doors for ease of field installation and connection

Cable entry from above or below the rubber seal / brush input, output

TS-3367 EN60439-1, EN60439-1 TS-3367 / A1

TECHNICAL SPECIFICATIONS;

Rated insulation voltage of 690 V

Rated operating voltage 400

Nominal frequency of 50 Hz

Rated current 400 up to

Protection Class IP 20 - IP 65

OPTIONAL FEATURES;

Front Door Glass or plexiglass from manufacturing

Color all RAL colors in paint manufacturing

Dimensions; Special production upon customer request

The ventilation system or air conditioning fan

CONTROL CONSOLES / SPECIAL PANELS

Product İnfo

Automation Control and Command Control stylish places requiring visual design and control is designed as a follow-up desks. Automation and control systems which are indispensable products. Electrostatic Epoxy polyester paint RAL 7035 (optional in all RAL colors) in a variety of thicknesses and sheet metal fabrication made from stainless steel. Ergonomic and stylish custom designs.

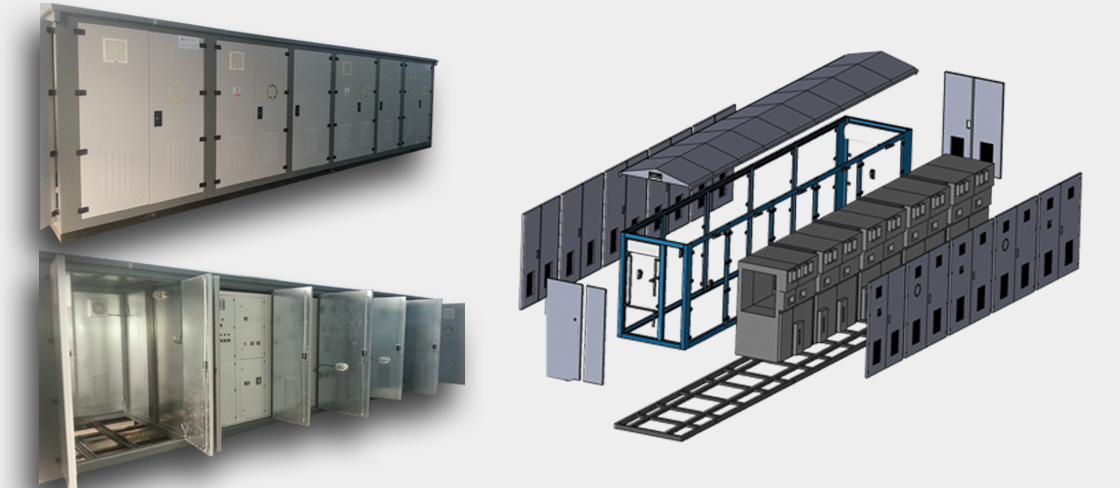

KIOSK SAC CELLS

Product Info

Cell Pavilion NPI frames of 100/120/160/200 mm profi? S are manufactured from. 1,5-2-2,5 mm mild steel outer body and lid are / is made of galvanized sheet metal and profile. Optional Sheet kiosk can be produced in as all RAL colors. The production is made in any color according to customer request. Sheet before Substations consist of 3 main parts. MV (Login) section of the Medium Voltage Cells are found. The middle section features determined according to customer requirements Transformers (Transformers) are available. AG (Output) The section has been designed according to customer requirements, electrical panels are used. Transformer Steel Kiosk equipment according to customer demand and may be in the desired dimensions.

- FOREIGN DIRECT DELIVERY BODY MANUFACTURING from dyed hair are 2-2.5 mm in thickness.

- REAR DOOR AND WHOLE BODY MANUFACTURING reinforced 2 mm thick are the dyed hair.

- WHOLE BODY WATER PROOF, SUN POWDER, is PAINTED TO FIT THE STORM CONDITIONS OF OUTDOOR TYPE POLYESTER.

- ALL FOREIGN BODY AND ROOF is 5-8 cm thick ISOLATION MATERIAL COVERED.

- Thermoregulator FRONT DOOR VENT FAN AND GRILL FOR THERE in.

- TRANSFORMER TRANSFORMER WITH INTERNATIONAL AND INTERNATIONAL PANEL should COMPARTMENTALISATION.

- LOWER MAIN TRANSPORT BAZAAR of 100/120/160/200 NP is the IRON PRODUCTION PROFILE

- ALL STAINLESS STEEL BODY ON THE MOVE BAZAAR MOUNT WITH BOLT is.

- INTERNAL BODY COVERING ON THE ISOLATION coated SAC 0.75 to 1 mm.

- ERECTION OF TRANSFORMER can MOVE MOVING IRON 100 NP is conducted.

INDUSTRIAL AUTOMATION

Product Info

Industrial automation, fast production process for the firm, accurate, easily renewable and, more importantly, provides the possibility to make low-cost production. An area which is very deep in terms of engineering and expense of the companies to reduce costs in the economic sense because it contributes also of great importance. In addition to the benefits of labor costs when compared with the long-term, the production of human production rate far ahead in terms of providing the ability to perform accurate and reliable manner is very important. Nowadays, every day is thought to play a little more active role in the robot industry, the importance of technology in industrial automation process will also be understood better. Technology is a friendly area for the realization of a lot of innovation in engineering, technology has come to be regarded as the future. The benefits provided by all the people, including industrial automation, consumer and reducing costs in the production process also means laughing face. Only manufacturers that provide benefits in terms of industrial automation, located in the ability to capture a stable level of economic supply and demand balance as a result of the long-term reduction of production costs while keeping them stable level of sales value of goods. Manufacturers can be precisely calculated using the production capacity of industrial automation systems, the future price analysis does correctly and may cause the price fixed by the capacity to meet demand.

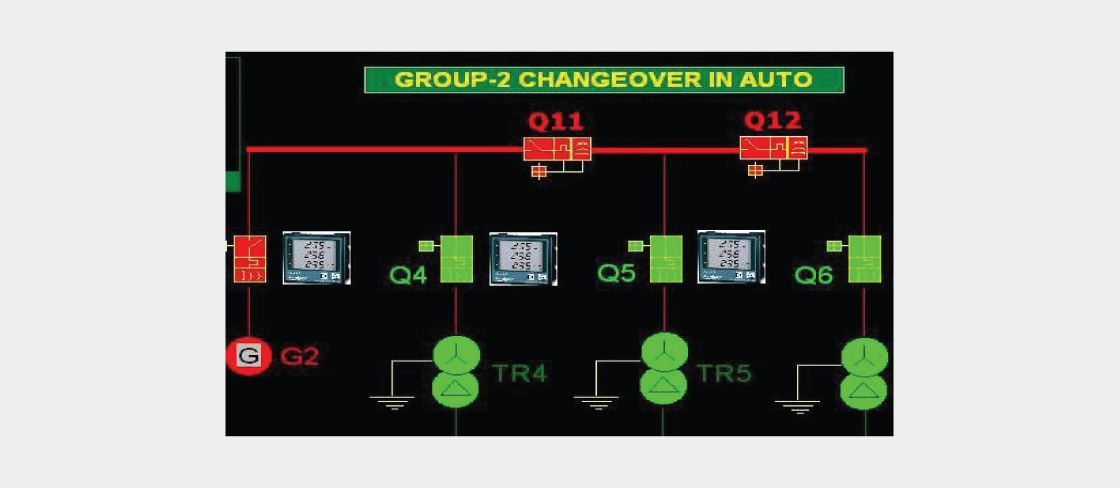

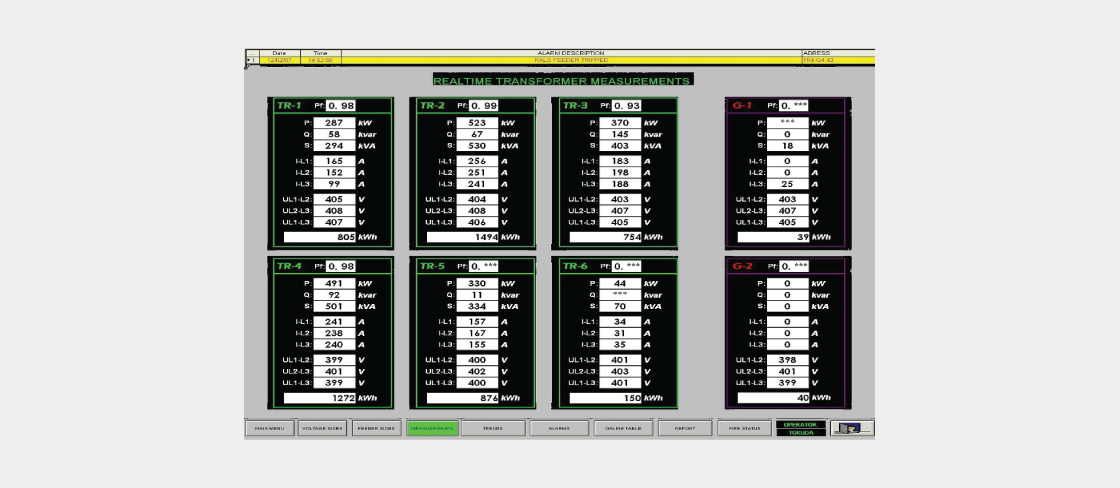

SCADA ENERGY APPLICATIONS

Product Info

Energy SCADA applications within the scope of the system in its entirety transformer, generator, UPS, LV distribution board, MV distribution cell, with the help of electrical arametr are energy analyzer on busbars Profibus / Modbus / with one of the Ethernet communication options is transferred to Siemens PLC. All data received through the energy analyzer WinCC SCADA software can be viewed on the PC screen. Also Transformer controls, generator control, automatically controlled by PLC automatically load things like throw. If desired automatic billing system can be designed with no additional software.

TREATMENT PLANT APPLICATIONS

Product Info

Physical Treatment

Coarse & Fine Screens

Pumping Station

Sand & Grease Removal

Balancing Pool

Chemical Treatment

Chemical Solution Preparation Units

Fast & Slow mixing Pools

Chemical Precipitation Pools

Biological Treatment

Denitrification Pools

Ventilation Pools

Biological precipitation Pools

Seawater Treatment

Ultra Filrasyo Units

Reverse Osmosis Units

Remi Units

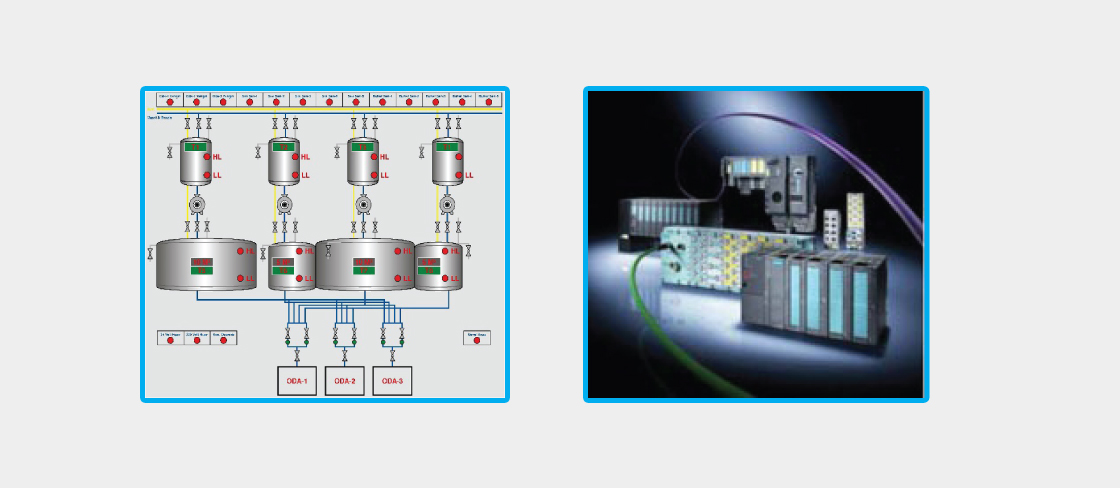

PLC & SCADA & OP APPLICATIONS

Product Info

PLC Applications

Programmable controllers are microprocessor-based devices. According to information received from the sensors transmit the work allotted to the program and actuators. The increase in production speed and provide a major contribution to the achievement of automation. Compact and themselves, with bilgisaya, can communicate with other intelligent devices. c Linear and rotary motion control can provide, temperature, pressure, humidity, speed, can control parameters such as weight.

SCADA Applications

The data collected by the PLC converted into electrical signals transmitted to the SCADA system. Drive motors, valves, lamps, speed measurement devices, approach detectors, temperature, force and torque sensors and electronics are located here. Are commanded by the SCADA system, in this layer, converted into electrical signals, the desired valve opening in the real world, by running the heater - ensuring the formation of movements like stopping.